Cutting Tools

Cutting tools are essential components in manufacturing and machining processes, used to shape, cut, or remove material from a work piece. They come in various types and materials, each suited to specific tasks and materials.

Bandsaw Blade

It is the Bandsaw Blade that is unbeatable when it comes to exact cutting. It provides smooth and accurate cuts, time after time, for both metal and wood. Durable and efficient, this tool should be at one's fingertips if top-notch results are what the workshop desires.

Circular Saws

Circular saws, designed with the greatest power and high precision, they are tools of great importance for any industrial cut. These saws deliver unbeatable degrees of accuracy and speed, hence fit for demanding environments where precision and performance must not be less than expected. Enjoy efficiency in every cut.

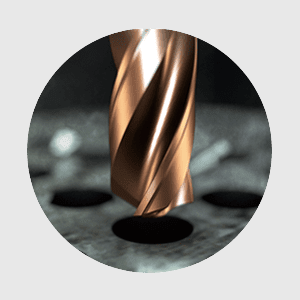

Drills

A holemaking process in which a rotating cutter makes a round hole in the workpiece to a certain depth. Drilling is often the first step in a series of holemaking operations. Able to be stretched, drawn, or formed without fracturing. Ductile metals tend to be soft and produce long, stringy chips.

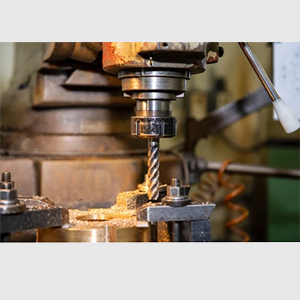

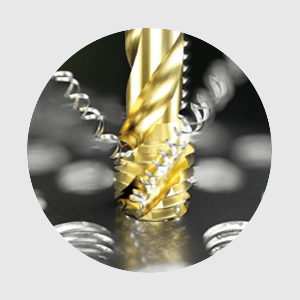

End Mills

End milling is the most versatile form of milling that can be used to machine slots, shoulders, die cavities, contours, and profiles. An end milling process consists of a cylindrical cutter that has multiple cutting edges on both its periphery and its tip, permitting end cutting and peripheral cutting.

Reamers

One of the precision tools used to enlarge or finish a drilled hole to accurate size with a smooth finish, reamers are quite appropriate in industries that require very fine tolerances. They improve the quality of metalwork by enhancing hole dimensions and surface texture in the manufacturing process.

Taps

Taps are some of the critical tools for precision machining that put threads in processed holes for caster bolts or any other form of fastening screws. These taps assure durability and accuracy more for perfection in an industrial touch. All this comes in various sizes to meet exact threading demand levels for increased production.

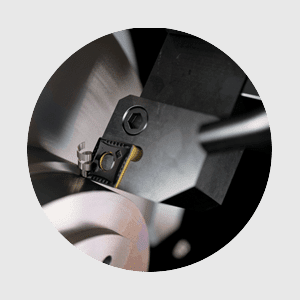

Inserts

Cutting inserts are divided into different types. This division specifically relates to the material they are made, its shape, dimensions, and applications. The most common are turning inserts, groove-turning inserts, inserts for cutting hard materials, and thread-turning inserts.

Broach Cutter

Broaches belong to the class of cutting tools that are mainly designed to shape materials with high accuracy. Engraving complicated profiles, they are an important tool in the automotive and aerospace industries and in metalworking. Smooth finishes and continuous results for every operation are guaranteed by our broaches.